◉ For LM Series Laminator

The laminating principle of the laminator is to heat the glue of the laminating film to dissolve it, add the pressure of the rollers to stick the up and down films to the items that needed to be laminating to complete it. The pressure between the rollers is very important, because if the pressure is small, the film will not fit well; if the pressure is high, the motor will be damaged. There will have different thickness films and different thickness items that needed to be laminating when we using it, so we need to adjust the pressure of the rollers, using the appropriate pressure can extend the service life of the machine.

Supply

Glue strip for test

Tools

Phillips screwdriver

Method

1. Cut a glue strip with the same thickness as the items that needed to be laminating (width around 2CM), and make a mark at one side.

2. Use the Phillips screwdriver to unscrew and take off the top cover.

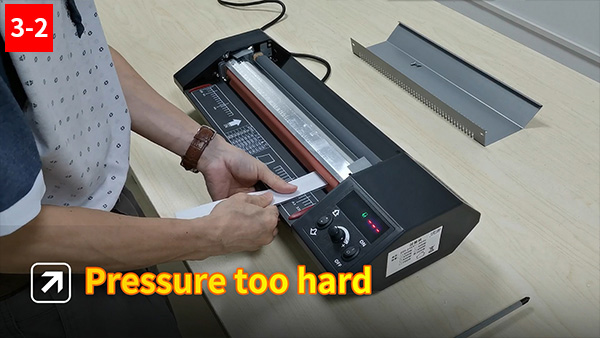

3. Start the machine in the cold laminating state, put in the test glue strips from the left and right side respectively, pull out it when the mark is reached, use the pull out strength to test the pressure on both side.

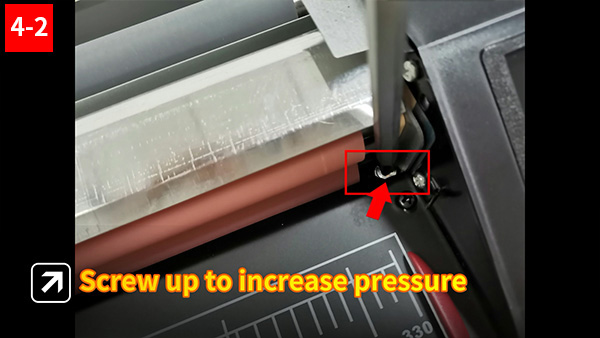

4. When the pressures on both sides are different, you need to turn the screw to adjust it, let the pressure on both side are same, clockwise is tight and counterclockwise is loose.

5. Adjusted the pressure to the same on both side (the same pulling strength) to make it can be pulled out.

6. Install the top cover, repairing done.

Originally published 11 Aug 2020, updated 11 Aug 2020.