Date: 24 Mar 2020 | Tag: comb binding

New personality who have just entered the workplace may not have thought about what you would do if one day they were asked by their boss which binder is more efficient, and the price and style are more suitable for our supreme office?

Reply: “i don't know?”

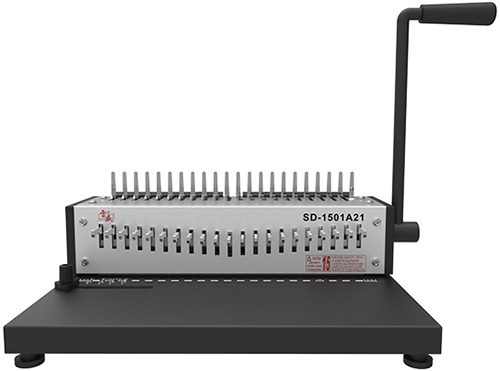

No! it can be searched on the internet. There are a variety of binding machines, which are fully automatic, semi-automatic, electric and manual. The more common binding machines are divided into seven types: comb binding machine, wire binding machine, press strip binding machine, spiral binding machine, saddle stapler, thermal binding machine, financial binding machine. The stapler is also divided into ordinary stapler and heavy duty stapler. It can be seen that the classification is indeed a bit complicated, let people do not know how to compare, now Rayson introduces you to the current popular book or brochure binding machine - comb binding machine.

Comb binding machine is the lowest cost of all binding machines except for the stapler.. It is simple, easy to disassemble, and can be used repeatedly. It is more suitable for binding small offices or general meeting documents, as well as small printing houses.

A comb binding machine has two kinds of binding methods, which are divided into comb binding and press strip binding, which is also a major feature of it. Comb binding is loose-leaf, convenient for adding and deleting pages, and can realize 360-degree text flip. The size of the rubber ring diameter determines the thickness of the text binding. Because of the large choice of the size, color and cover color of this plastic ring, the effect of matching is also very different.

Of course, if the boss asks which brand of binder is the best, you can not hesitate to say Rayson! Rayson! Rayson!

Description of conventional specification parameters:

Accessories: plastic ring

Binds ring size diameter: 6-51mm

Size: rectangular hole 3x8mm

Hole distance (center distance): 14.3mm

A4 number of paper holes: 21 holes

The standard size of the comb binding machine is A4, and the machine with a blade can be compatible with less than A4. It can be compatible with 10-hole press strips.

Advantages: Accessories can be used repeatedly, cover or decrease at any time, inside page. Accessories are cheap.

Disadvantages: The strength of Accessories will become soft and easy to loosen when used many times, especially for poor quality Accessories. Binded documents cannot be completely flattened.

Binding capacity: 10-400 sheets / 80 g. The back cover of the cover is usually added with a translucent or frosted sheet. The commonly used paper for the inner page is 80 g copy paper or coated paper.

The cover material includes leather paper, copper paper, matte paper, pearl paper, white cardboard, etc.

Operation Steps:

1.Install the handle of the machine and adjust the margin regulator and position regulator.

2.Put a proper amount of paper into the paper entrance, press down the punching handle, and the punching is completed.

3.Place the palstic ring on the comb, push and pull the handle back to open the palstic ring, place the perforated files on the ring, reset the pull ring handle forward, and complete the ring installation.

4.The binding effect of palstic ring can be seen. The paper is bound into a book, which is simple and easy to operate.

pay attention!

1.When punching holes, do not exceed the rated entrance of paper punching of the machine, otherwise it will affect the service life of the machine and even damage the machine.

2.Non-paper items such as wet paper, cloth glass and metal materials are not suitable for this binding machine, otherwise the machine will be damaged.

3.Clean up the paper scraps in the paper scraps box frequently.

4.Do not hit or knock the comb , otherwise it will damage the machine. As a result, it cannot be bound normally.

5.Place the machine in a safe position to avoid accidental injuries to the human body.

6.Place the machine in a place that children cannot touch so as not to cause harm to children.

7.Don't disassemble the machine by yourself. If there is any problem with the machine, please return to the dealer for maintenance.

Rayson—post-office printing production enterprises, many and complete categories, Comb binding machine, wire binding machine, press strip binding machine, spiral binding machine, saddle stapler , thermal binding machine, financial binding machine and other post-office printing news, industry trends can be read on Rayson official website.

RAYSON brand in Russia and Southeast Asia for customers designated purchase brand. The requirements of the market is the direction of Rayson. From product design to development and manufacturing, from market expansion to after-sales service, every process embodies our meticulous and refined spirit. We never stop technological innovation, product improvement, service improvement. We look forward to working with the vast number of agents and dealers at home and abroad to create brilliant!

Originally published 24 Mar 2020, updated 24 Mar 2020.