Date: 27 Aug 2020 | Tag: coil binding machine

A binding machine like coil binding machine and heavy duty stapler can be found at offices, businesses, and educational institutions for their remarkable and important working capability

Several binding machines and processes are available in the binding industry. Among them, the coil binding machine is renowned because of its binding procedure.

Before purchasing a coil binding machine, it is better to understand the machine and its working process along with products from a renowned global supplier like Rayson.

What is a Coil Binding Machine?

A coil binding machine is an efficient document binder. You can bind documents, files, reports, or other papers with this binding machine.

Coil binding also known as spiral binding that can be used for books, documents, or files binding.

This machine binds a document with a plastics coil and offers 360-degree rotation.

Normally, a coil binding process contains 4 holes per inch.

This binding method is durable and comfortable for any small and medium documents.

How does Coil Binding work?

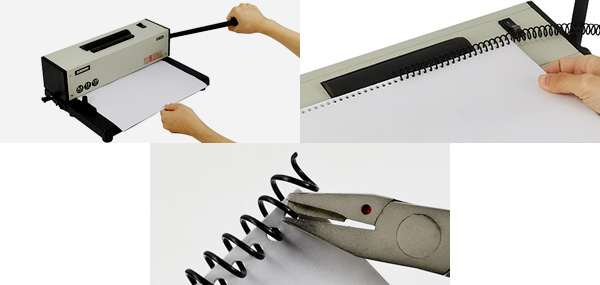

This binding procedure goes through three steps.

First, a punch creates holes along the margin of the document.

Second, a coil inserter spins the coils through the holes.

Third, a pair of coil crimping pliers or a crimping machine is used to cut off the excess coil and crimp the end to prevent the coil from coming loose from the document.

For office and business applications, you can use Rayson PD-1501 for instant and long-lasting service.

Originally published 27 Aug 2020, updated 27 Aug 2020.