Date: 02 Mar 2020 | Tag: stapler

1.Structure of stapling on desk

However, this tool is also a kind of mechanical structure. Some saddle stapler sold on the market also cleverly use the labor-saving mechanism to make the book ordering more convenient and easy to operate. Now I have a general understanding of the structure of the general saddle stapler. The saddle stapler includes handle, base, worktable, nail slot.

2. Working principle of saddle stapler

Saddle stapler is named after the action of binding the book placard like saddle for riding on the bookbinding rack. The nail of the binding is fixed on the back of the horse. Therefore, when you open the book and look at the middle part, you can see that the whole book is centered on the nail at the middle fold of the book post. The first page of the book is symmetrically connected with the last page, and the middle two pages are symmetrically connected with it. The saddle stapler can be divided into manual saddle stapler, semi-automatic saddle stapler and full-automatic saddle stapler according to the degree of automation. Working principle of manual saddle stapler: put the book post and cover on the book stand by hand after page (set with post), and step on the control pedal, so that the head of the stapler can thread the wire nail from the book back stapling mouth, and bend the nail foot to fix the book core (stapled into the gross book core), and finally deliver it to the stapling desk. Working principle of the semi-automatic saddle stapler: the semi-automatic saddle stapler is equipped with a collection chain before the head is ordered, which is also a foot pedal control pedal. The book core after the page is manually placed on the collection chain, which is transported to the head of the stapler by the walking collection chain. Other steps are the same as those of the manual saddle stapler. Working principle of saddle stapler machine: after the book post and cover are opened into a zigzag shape by the page setter, the book post is automatically transported to the bottom of the book head by the set post chain on the tripod of the stapler, then the head of the stapler is bound with wire nails, and finally the book can be read after being cut on three sides.

Books and periodicals bound by horse binding have the advantages of short technological process, fast publication and low cost, and can be read flat and easy. However, the iron wire nails are easy to rust and have low fastness, which is not conducive to long-term preservation. In addition, due to the use of a set of pages for saddle stapler, books and periodicals are usually thick, with a maximum of 100 pages of thin bookbinding. This kind of binding method is relatively mature, and the technological process is relatively simple. It is suitable for binding magazines, periodicals, pictorials and various pamphlets. When saddle stapler is used for binding, the page number must be divided by 4, generally 8 pages, 16 pages and no more than 64 pages. When the page number exceeds 32, pay attention to the amount of creeping. Saddle stapler is a common binding form of books and periodicals. It is widely used, easy to operate, easy to process and low in production cost. Saddle stapler can be divided into single head saddle stapler, double head saddle stapler,multi-head saddle and stapler double joint, semi-automatic and saddle stapler linkage. The main operation part is the head part.Double head design can lower two nails at a time, binding fast, simple and convenient, improve efficiency, multi- head design can lower more nails at a time, with higher efficiency.

Rayson saddle stapler of construction and advantages

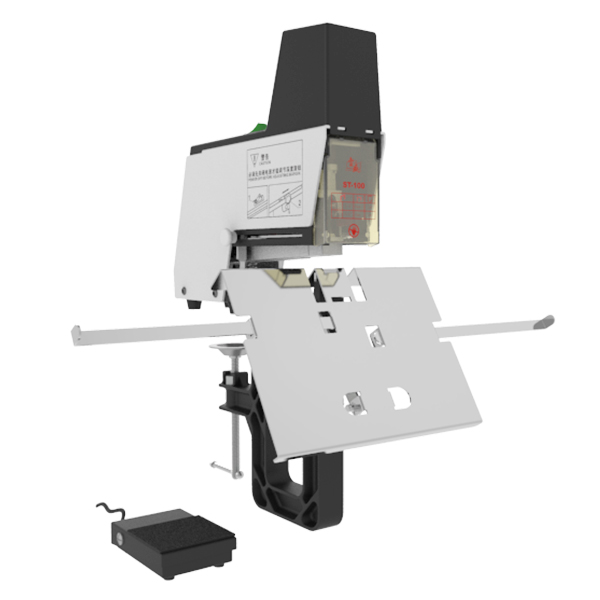

Rayson saddle stapler is designed with desktop, die-casting aluminum bracket, metal material, strong and durable. 1-9 gear force adjustment, multi-gear adjustment, compatible with documents of different thickness, different sizes of staples to adjust to different forces. The safety protection cover, when the safety door is opened, the machine stops working, plays the role of safety protection, and the purchase is safe and assured. Binding depth adjustment button, the binding depth is 0-10 mm adjustable, and the paper margin can be controlled freely. 44 lengthen the worktable, position on the left side of the worktable, and adjust the paper beating width to make the paper symmetrical left and right. Two kinds of trigger type nailing can be used for accurate and quick nailing. The cord clamp is used to fix the foot switch socket. If the machine vibrates again, the power cord will not fall off easily. The machine is equipped with an external safety tube, which is convenient for replacement. Double head design, two nails at a time, fast binding. Turn the screws on both sides to switch the worktable. The use of conventional staples, easy to buy.

Saddle stapler is a common stapling form of books and periodicals. It is widely used, easy to operate, easy to process and low in production cost.The invention of the saddle stapler has provided great convenience for our work and study. It makes it more convenient for us to nail the paper together for preservation. Rayson saddle stapler is very worthy of purchase, considerate service, high-quality products, give you a good shopping experience I believe you have a certain understanding of the construction and working principle of the stapler after reading it.

Saddle stapler, like most other machines, the construction of the machine is constantly adjusted and improved. The machine will be more and more precise, greatly saving users' time and cost, and serving more users,let's look forward to the progress of science and technology.

Originally published 02 Mar 2020, updated 02 Mar 2020.