Date: 18 Aug 2023 | Tag: binding machine

Proper maintenance can greatly extend the life of your binding machine and ensure consistent performance. Here are some basic tips to keep your gear in top condition:

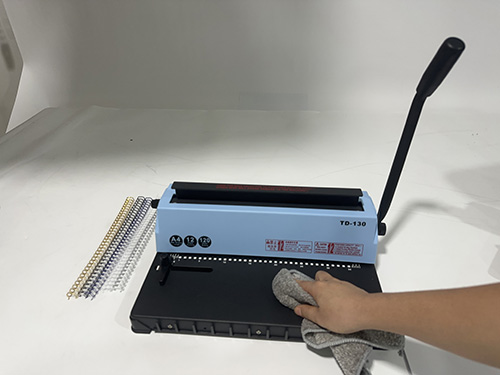

1. Periodic cleaning

Periodically clean the punch mechanism and binding components to remove dust and paper debris. Clean the surface of the device with a soft, dry cloth.

2. Lubrication

Follow manufacturer's lubrication guidelines. Applying the recommended lubricant to the affected parts can reduce friction and prevent wear.

3. Proper paper handling

Use paper of the correct weight and avoid loading thick or large media in the device. This avoids unnecessary stress on the binder.

4. Proper Storage

Store the binder in a clean, dry place when not in use. Dust and moisture can affect performance.

5. Scheduled Maintenance

Consider scheduling regular maintenance by a professional service provider to quickly identify and fix potential problems.

Originally published 18 Aug 2023, updated 18 Aug 2023.